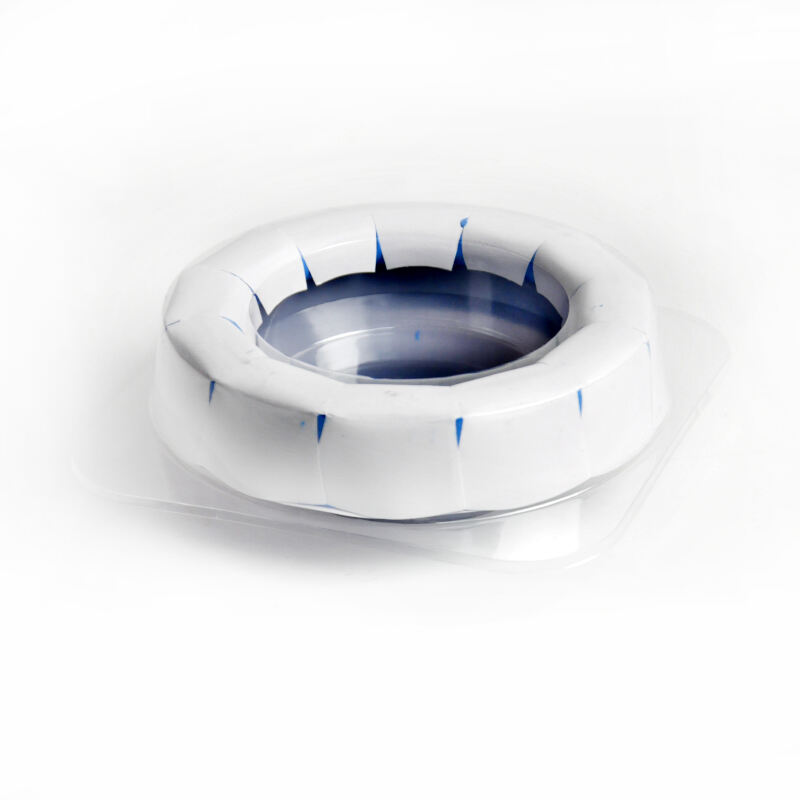

A plumbing wax ring is a fundamental sealing component used in toilet installations to create a watertight and gas tight barrier between the toilet bowl and the floor flange, preventing leaks, sewer gas emissions, and odor infiltration. This essential plumbing supply has been a staple in the industry for decades, valued for its simplicity, reliability, and ability to conform to irregular surfaces that rigid materials cannot seal effectively. Composed of a blend of petroleum based waxes, microcrystalline waxes, and reinforcing materials such as fiber mesh or a plastic core, plumbing wax rings leverage the malleability of wax to form a custom seal when compressed by the weight of the toilet. The wax mixture is carefully formulated to balance flexibility and structural integrity: it is soft enough to fill micro gaps between the toilet base and flange yet firm enough to maintain its shape under pressure, resisting extrusion into the drain pipe. Most plumbing wax rings feature a central cone shaped horn that extends into the drain opening, enhancing the seal at the critical connection point and preventing wax from entering the plumbing system, which could cause clogs. The outer diameter of the ring is sized to cover the flange opening completely, ensuring a comprehensive seal around the perimeter. Installation involves placing the wax ring centered on the flange, with the horn facing upward, then lowering the toilet onto the ring to compress the wax uniformly. Proper installation requires avoiding rocking or twisting the toilet, which can displace the wax and create leaks. Tightening the toilet bolts gradually secures the fixture while maintaining optimal compression of the wax. Plumbing wax rings are compatible with standard 3 inch and 4 inch drain flanges, making them suitable for most residential and commercial toilet installations. They work effectively with various flange materials, including PVC, cast iron, and brass. While modern alternatives like rubber seals exist, wax rings remain popular due to their cost effectiveness, universal compatibility, and proven performance in standard installations. In colder environments, wax rings may require handling with care to prevent brittleness, but their sealing properties are restored once compressed and warmed by the ambient temperature. Regular inspection for signs of wax degradation—such as leaks around the toilet base or sewer odors—ensures timely replacement, typically every 5 to 10 years depending on usage and conditions. By providing a reliable seal that adapts to real world installation imperfections, plumbing wax rings continue to play a vital role in maintaining the functionality and hygiene of bathroom plumbing systems.