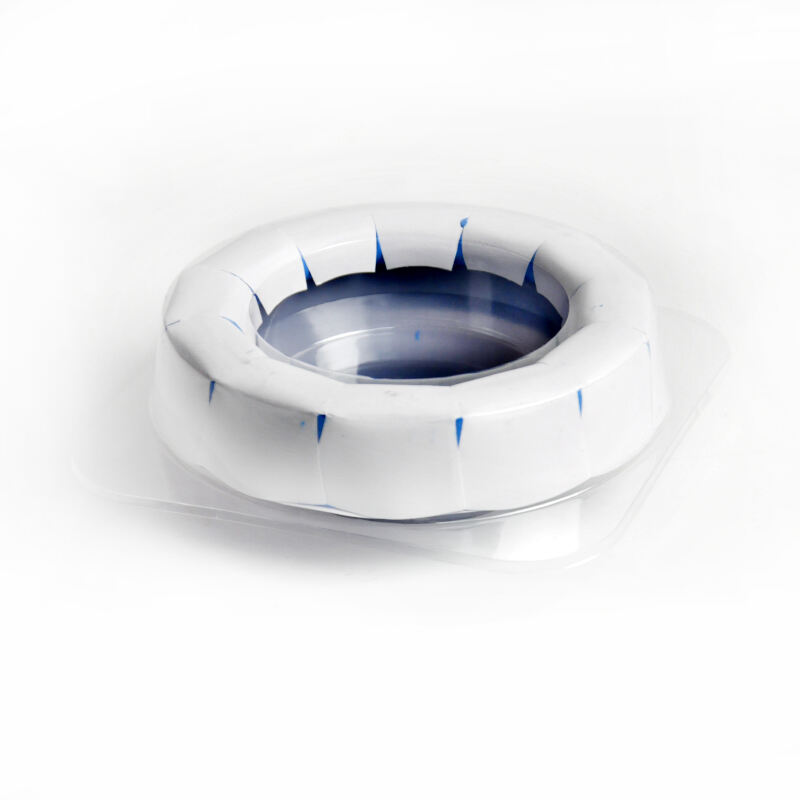

A toilet flange rubber seal is a modern alternative to traditional wax rings, designed to create a watertight and gas tight barrier between the toilet bowl and the floor flange. Made from high quality, flexible rubber or elastomeric materials, this sealing component offers superior durability and versatility compared to wax based solutions, making it a popular choice for both residential and commercial plumbing installations. The rubber seal is engineered to compress when the toilet is installed, conforming to irregular surfaces and creating a custom fit that adapts to minor imperfections in the flange or toilet base. Unlike wax, which can become brittle over time and lose its sealing properties, rubber maintains its elasticity even after years of use, ensuring long term reliability. This resilience makes rubber seals particularly effective in environments with fluctuating temperatures, such as basements or attics, where traditional wax rings may fail due to repeated expansion and contraction. The design of a toilet flange rubber seal typically includes a circular base that sits on the flange, with a central sleeve or horn that extends into the drain pipe to prevent leaks at the connection point. Many models feature a ribbed or textured surface that enhances grip, preventing slippage during installation and ensuring a secure seal. Some rubber seals also incorporate a metal or plastic reinforcement ring to provide structural stability, preventing over compression and maintaining the seal’s integrity under the weight of the toilet. Installation of a rubber seal is straightforward and less messy than working with wax rings. The seal is placed on the flange, aligned with the drain opening, and the toilet is lowered into position. The weight of the toilet compresses the rubber, creating an immediate seal that requires no waiting time for setting or curing. This simplicity makes rubber seals ideal for DIY installations, as they reduce the risk of improper sealing due to uneven wax compression. Additionally, rubber seals are reusable if carefully removed during toilet maintenance, unlike wax rings, which must be replaced after each removal. Rubber seals are compatible with most standard toilet flanges, including PVC, cast iron, and brass, and work with both floor mounted and wall hung toilets. They are resistant to water, chemicals, and microbial growth, ensuring hygiene and performance in humid bathroom environments. In commercial settings with heavy toilet usage, such as hotels, schools, and airports, rubber seals offer enhanced durability, reducing the need for frequent replacements and minimizing maintenance costs. While rubber seals may have a higher initial cost than traditional wax rings, their longevity and reusability make them a cost effective choice over time. They eliminate the risk of wax extrusion into drain pipes, which can cause clogs, and provide a more consistent seal across various installation conditions. For homeowners and plumbers seeking a reliable, mess free sealing solution, the toilet flange rubber seal represents a significant advancement in plumbing technology, combining ease of use with long term performance.