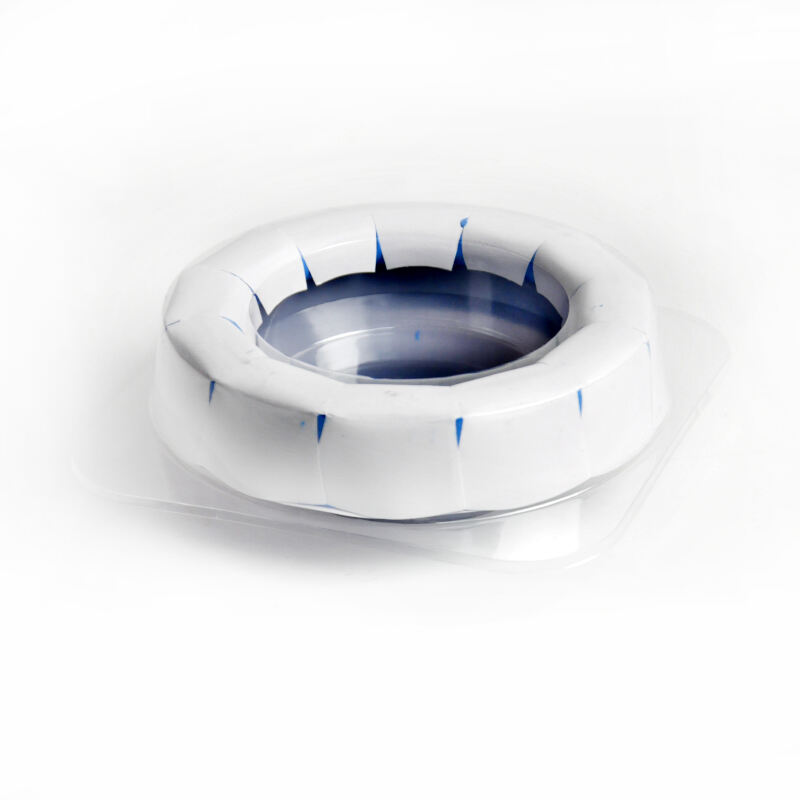

Toilet rings encompass a range of essential plumbing components designed to create seals between various parts of a toilet system, with primary types including wax rings, rubber rings, and foam rings that prevent water leakage and sewer gas emissions. These rings serve as critical barriers at the interface between the toilet bowl and floor flange, as well as between the tank and bowl in two piece toilets, ensuring the plumbing system operates efficiently while maintaining hygiene in the bathroom. The most common type, the wax toilet ring, is composed of a malleable blend of petroleum and microcrystalline waxes, often reinforced with fiber mesh or a plastic core. It compresses when the toilet is installed, conforming to irregular surfaces to create a watertight seal between the bowl’s outlet and the floor flange. Wax rings are valued for their cost effectiveness and reliability in standard installations, though they can be messy to handle and require replacement after each toilet removal. Rubber or silicone toilet rings represent a modern alternative, offering flexibility, reusability, and easier installation. These rings maintain elasticity over time, resisting degradation from water and temperature fluctuations, and can often be reused if carefully removed during maintenance. They create a secure seal without the mess of wax, making them popular for DIY projects and commercial settings with frequent maintenance needs. Foam toilet rings, another option, combine foam’s compressibility with a rubber core, providing a lightweight, mess free solution that works well for flange heights slightly below floor level. Beyond bowl to flange seals, toilet rings include tank to bowl gaskets—typically rubber or foam rings that prevent leaks between the toilet tank and bowl where they connect. These gaskets ensure water from the tank flows properly into the bowl during flushing without seepage. Some toilet rings feature specialized designs, such as extra thick rings for recessed flanges, offset rings for misaligned drains, or odor blocking rings with gas impermeable barriers. Installation practices vary by ring type but generally involve centering the ring on the flange, aligning the toilet, and compressing the ring evenly. Proper selection depends on factors like flange condition, installation environment, and user preference, with wax rings remaining reliable for standard use and rubber/foam rings offering advantages in specific scenarios. Regular inspection of toilet rings for signs of wear—such as leaks, odors, or a loose toilet nsures timely replacement, preventing water damage and maintaining bathroom hygiene. By creating essential seals at critical junctions, toilet rings play a vital role in the functionality, safety, and longevity of toilet systems in both residential and commercial applications.