Understanding the Function and Importance of a Toilet Wax Ring

What Does a Toilet Wax Ring Do for a Toilet?

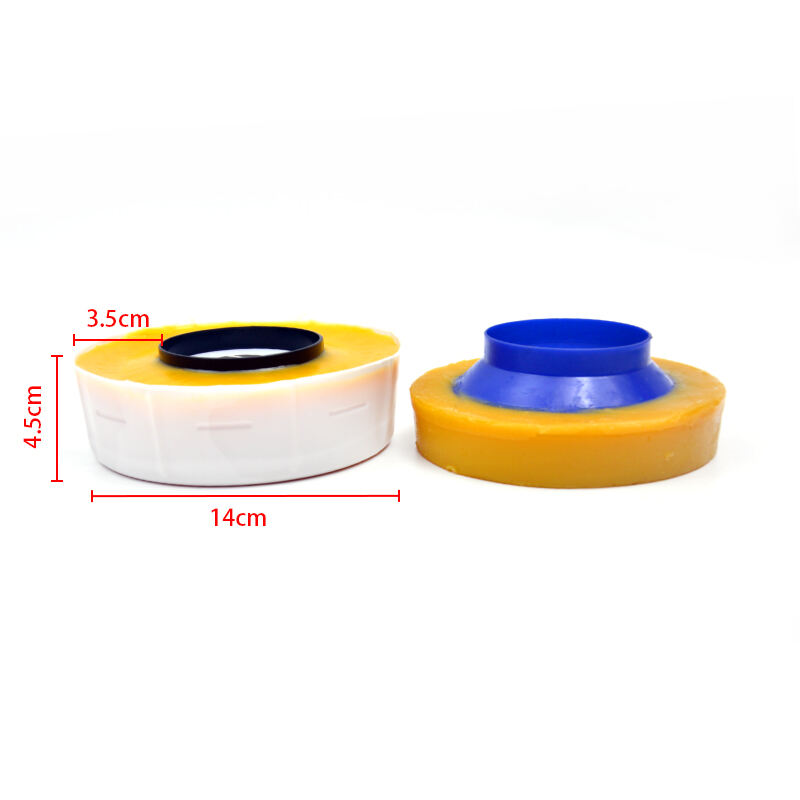

A toilet wax ring creates a watertight and airtight seal between the toilet base and the drain pipe, preventing leaks, sewer gas odors, and microbial contamination. Made from pliable materials like beeswax or synthetic compounds, it conforms to minor irregularities between the toilet flange and floor.

The Role of a Toilet Wax Ring in Creating a Secure Seal Between the Toilet and Drain Flange

When compressed during installation, the wax ring fills gaps up to 1/8" (3.2 mm) caused by uneven surfaces or misaligned flanges. According to the 2024 Plumbing Materials Report, properly installed rings can last 20–30 years in residential settings. This durability is critical, as seal failures contribute to 68% of bathroom water damage claims (NAHB 2023).

Toilet Wax Ring Purpose in Residential vs. Commercial Plumbing Systems

- Residential: Standard 1"–1.5" thick wax rings are sufficient for typical household use.

- Commercial: Reinforced or extra-thick rings (up to 3") handle frequent usage and structural vibrations. These systems often favor wax-free alternatives like neoprene for easier servicing in high-traffic environments.

Types of Toilet Wax Rings and Their Best Applications

Standard, Extra-Thick, Reinforced, and Deep-Seal Wax Rings: When to Use Each Type

Regular wax rings do the job fine as long as the toilet flange is sitting roughly a quarter inch above the finished floor surface. When dealing with those tricky situations where the flange is set back into the floor or the subfloor isn't level, going for thicker wax rings makes all the difference. For bigger gaps between the toilet base and the flange, deep seal models come into play. Some wax rings have been reinforced with plastic cores made from either polyethylene or PVC material. These stronger versions hold their shape better when someone needs to adjust the positioning after setting it down, which happens more often than people realize. That's why plumbers often recommend them for commercial bathrooms or any location where things need to stay put for years without issues.

Neoprene and Wax-Free Alternatives as Emerging Options

Wax-free seals made from neoprene or thermoplastic polymers offer reusability (3–5 installations vs. single-use wax) and cleaner handling. In earthquake-prone regions, these alternatives demonstrated a 40% reduction in seal failures compared to traditional wax, according to the 2024 Plumbing Materials Report.

What Are Reinforced Wax Rings and How Do They Improve Installation Stability?

Reinforced wax rings include a rigid plastic collar embedded within the wax, which prevents lateral shifting if the toilet rocks or settles. This design reduces the risk of seal fractures, especially important in high-traffic bathrooms with over 150 daily flushes.

Pros and Cons of Reinforced vs. Regular Wax Rings

| Feature | Reinforced Wax Rings | Regular Wax Rings |

|---|---|---|

| Installation Stability | Resists shifting during adjustments | Prone to deformation |

| Durability | 10–15 year lifespan | 5–8 year lifespan |

| Cost | $12–$18 per unit | $5–$10 per unit |

| Best For | Commercial, uneven floors | Standard residential |

While reinforced models reduce long-term maintenance needs, they come at a 30% higher upfront cost. DIY installations typically favor standard rings unless dealing with complex alignment issues.

Material Quality and Environmental Factors in Wax Ring Selection

Common Materials: Beeswax, Petroleum-Based Compounds, and Synthetic Blends

Today's wax rings come in three main types that try to find the sweet spot between how they work and their impact on the environment. Beeswax is all natural stuff that breaks down over time, works great in normal weather conditions, though it starts getting gooey when temperatures climb past around 120 degrees Fahrenheit. Most businesses stick with petroleum-based products because they hold up better structurally. These last about 85% as good after sitting there for five whole years, which makes them pretty reliable for long-term installations. Then there are these synthetic mixes that throw together some polymers and old wax materials. They actually stick better than regular ones by about 20%, plus they check off those EU REACH requirements so companies can sell them across Europe without running into regulatory problems.

| Material | Best Use Case | Temperature Range | Environmental Impact |

|---|---|---|---|

| Beeswax | Low-traffic homes | 40°F–120°F (4°C–49°C) | Biodegradable, non-toxic |

| Petroleum-Based | Commercial/High-Use Settings | -20°F–160°F (-29°C–71°C) | Non-recyclable, VOC emissions |

| Synthetic Blends | Humid/Coastal Regions | -40°F–180°F (-40°C–82°C) | 30–50% recycled content |

Performance in High-Humidity, Extreme Temperature, and Corrosive Environments

Along coastlines like those found in Florida or parts of Southeast Asia, rings made with synthetic polymers cut down on corrosion problems around 63% better than regular wax according to some research from last year's Marine Plumbing Study. The petroleum-based seals stay pliable even when temperatures drop below zero degrees Fahrenheit, which makes them much better suited for places where it gets really cold compared to good old-fashioned beeswax. For installations located close to factories or heavy industry areas, plumbers often recommend going with neoprene reinforced seals instead. Why? Because those nasty acidic fumes coming off sewers can eat away at wax coatings about four times quicker than normal conditions would allow.

Long Term Durability Based on Material Composition Across Different Markets

The folks in Nordic countries really stick with those high-density petroleum wax rings when it comes to dealing with frost heave issues, taking up around 98% of the market there. Down under in Australia, plumbers have noticed something interesting too. They're seeing about 85% of these synthetic versions still working after a decade, especially in areas where termites are a big problem. Now take a look at places prone to earthquakes like California. Hybrid wax rubber seals actually tend to last about 40% longer because they can handle all that shifting and movement in buildings that would just crack regular materials apart. And speaking of regulations, never forget to check what's required locally. Take California's Title 24 code for instance. It specifically calls for low VOC formulations, which basically means goodbye to most of the traditional petroleum-based rings on the market today.

Wax Ring vs. Rubber Seal: Comparing Traditional and Modern Solutions

Wax-free vs. Wax Seals: Differences in Durability, Reusability, and Ease of Installation

Old fashioned wax seals stick right away when compressed but they tend to break down quicker when temperatures fluctuate, usually good for around 5 to 8 years inside residential settings. The newer options without wax such as neoprene or thermoplastic types let folks adjust them while installing and can handle about 30 percent extra compression before failing according to some research published last year by plumbing material experts. Still worth noting though these modern seals are stiffer which actually makes leaks more likely if the flange surface isn't perfectly flat something plumbers run into all too often on real-world jobs.

Market Trends: North America's Preference for Wax Rings vs. Europe's Shift Toward Rubber Seals

Most installations in North America continue to rely on wax rings because people know them well and they cost less money around $3 to $10 compared to rubber options which run between $15 and $30. Meanwhile across Europe, 22 different countries have actually made it required by law to install these reusable seals instead. The reason? They want to cut down on all that trash ending up in landfills from those one-time use wax rings. So what does this mean? Well basically there's a big difference between regions when it comes to making choices about bathroom fixtures. Americans tend to pick whatever is cheapest and easiest, whereas Europeans care more about keeping their environment clean and sustainable over time.

Are Wax-Free Seals Outperforming Traditional Wax Rings in Commercial Applications?

Rubber seals offer an 18% longer service life in high-traffic facilities with routine maintenance. Though they demand precise flange alignment, their resistance to harsh cleaning chemicals gives them an edge over wax. For operations targeting decade-plus reliability, hybrid seals—combining wax’s adaptability with rubber’s resilience—are increasingly favored.

Key Selection Criteria for Toilet Wax Rings Across Global Markets

Matching Wax Ring Type to Flange Height, Toilet Horn Length, and Floor Conditions

Getting the right fit starts with checking three key measurements: how high the flange sits, the length of the toilet horn, and where the floor actually is. When dealing with those old European style installations where the flange sits below floor level, most plumbers will tell you that an extra thick wax ring or some kind of spacer becomes necessary. The newer flush mounted flanges we see throughout North America these days generally pair well with regular size rings though. And let's face it folks, when people mix up these components they're asking for trouble. According to Plumbing Standards Quarterly from last year, about one out of every four toilets leaking worldwide happens because the parts just don't compress properly together.

Understanding Size Variations: Diameter, Thickness, and Offset Flange Compatibility

Regional plumbing standards influence sizing needs. North American systems usually require 3-inch diameter rings, while Asian and Middle Eastern installations often use 4-inch versions for wider waste pipes. Offset flanges—frequent in renovated European properties—need tapered or reinforced rings to bridge gaps without splitting.

Can You Stack Two Wax Rings? Risks and Manufacturer Guidelines

Stacking wax rings is discouraged despite its popularity in DIY repairs. Testing shows double-stacked rings fail 37% faster under temperature changes due to uneven compression (Global Plumbing Journal, 2024). Most manufacturers prohibit stacking in warranty terms, recommending spacer kits instead for low-flange scenarios.

Regional Standards and Installation Practices Influencing Toilet Wax Ring Choice

Installation practices vary widely. North America maintains a strong preference for wax rings (52.3% market share), whereas Scandinavian countries increasingly adopt rubber gaskets for freeze resistance. In tropical markets like Southeast Asia, synthetic blends outperform traditional beeswax thanks to superior performance in 90% humidity, as highlighted in regional infrastructure analyses.