Compliance with ADA and IRC Safety Standards

Understanding ADA Compliance and Accessibility Guidelines for Safety Grab Bars

According to ADA Accessibility Guidelines, safety grab bars should have a diameter of about 1.25 inches so people can grip them securely. Horizontal bars need to sit between 33 and 36 inches from the floor surface. These measurements help prevent slips and falls among folks who struggle with mobility issues. The ADA mainly focuses on horizontal bars when someone needs to transfer from one position to another. However, building codes like the International Residential Code actually bring in ANSI A117.1 standards via the International Building Code. This means shower and bathtub areas must include extra vertical bars too, which helps those sitting down get up safely. Looking at recent data from the 2024 Facility Safety Report, around 78 percent of healthcare facilities already include these vertical bars in their design plans.

IRC Requirements for Bathroom Safety and Structural Support

When it comes to building codes, the IRC really focuses on making sure things hold up under pressure. The code actually requires grab bars to be attached to either wood studs or steel blocks that can handle at least 250 pounds of force. This is different from what the ADA mainly cares about with accessibility standards. What matters most for the IRC is creating something that won't give out when needed most, especially in places like assisted living communities where people rely heavily on these safety features. And let's face it, bad installation work leads to problems down the road. Studies show around 41 percent of all grab bar failures happen because they weren't installed properly in the first place.

How Reputable Suppliers Demonstrate Code Compliance and Certification

Top manufacturers verify compliance through ISO/IEC 17025-accredited laboratory testing, providing documentation on material strength, corrosion resistance, and load-bearing performance. Products should carry dual certification marks (ADA and ANSI A117.1) and may include ASTM F446-21-compliant antimicrobial surface treatments to enhance hygiene in clinical settings.

Addressing the Gap Between Standards and Real-World Installation Practices

A 2023 survey of 200 contractors found that 63% encounter non-compliant wall assemblies during retrofits. To bridge this gap, leading suppliers offer adjustable mounting plates, tile reinforcement kits, and BIM-compatible installation guides that align code requirements with real-world construction variables.

Weight Capacity and Structural Performance (250+ lbs Load Rating)

Minimum Weight Capacity Standards for Commercial-Grade Safety Grab Bars

Hospitals, assisted living facilities, and other commercial spaces need grab bars that can handle at least 250 pounds of weight according to ADA guidelines (Section 609.3). These standards exist because people come in all shapes and sizes, from those who are fully mobile to individuals relying on walkers or wheelchairs. Top quality manufacturers often go beyond these requirements, building grab bars capable of supporting between 300 to 400 pounds. Why? Because when someone loses balance or starts to fall, there's actually much more force acting on the bar than just body weight alone. The extra strength helps prevent accidents and gives users peace of mind knowing they have solid support when needed most.

Testing Methods for Load Bearing Strength and Long-Term Durability

Structural reliability is confirmed through:

- Static load testing: Application of 250+ lbs of vertical force for at least 5 minutes

-

Cyclic load testing: Repetitive 150-lb applications simulating over 10 years of daily use

Third-party certifications such as ANSI/BHMA A156.23 validate adherence to these rigorous protocols, which exceed residential standards by up to five times.

Case Study: Failures Due to Inadequate Weight Support in Healthcare Facilities

The Healthcare Safety Institute looked into 87 instances where hospital grab bars failed, and they found something surprising: nearly a third of those incidents happened with patients who weighed less than 200 pounds. What went wrong? Many installations used poor quality anchors, and some facilities even installed hollow core steel bars that were sold as commercial grade products. The numbers tell a story too. When these accidents happen, settlements typically run around $740,000 according to Ponemon's research from last year. This highlights why hospitals need to actually check out the certified testing reports instead of just taking what manufacturers say at face value.

Material Quality and Corrosion Resistance (Stainless Steel vs. Alternatives)

Comparing Materials: Stainless Steel, Brass, Aluminum, and Reinforced Plastic

Safety grab bars must balance strength, durability, and environmental resilience. The most common materials are evaluated below:

| Material | Corrosion Resistance | Maintenance Needs | Load Capacity | Cost Profile |

|---|---|---|---|---|

| Stainless Steel | High (chromium oxide layer) | Low | 500+ lbs | Higher upfront |

| Brass | Moderate (requires coatings) | High | 350–400 lbs | Moderate |

| Aluminum | Moderate (prone to pitting) | Medium | 250–300 lbs | Lower upfront |

| Reinforced Plastic | High | Low | 200–250 lbs | Cost-effective |

Stainless steel works really well in damp places because it has this natural chromium oxide layer that basically fixes itself when damaged. No need for extra coatings like other metals require, according to those corrosion tests we all know about. Brass looks great on fixtures and furniture but needs constant attention - polish it once a month or watch it start to break down. Aluminum is light and cheap to work with, which makes it popular for many projects. However, it gets those little pits from corrosion if not properly maintained. Reinforced plastics can handle harsh chemicals and stay dry without problems, but they just don't hold up under serious stress or weight. That's why most industrial equipment still relies on metal despite the plastic alternatives available today.

Why Material Choice Affects Safety, Longevity, and Maintenance Costs

Healthcare facilities lose around $740,000 every year due to corrosion problems in their safety equipment according to a study by Ponemon from last year. When it comes to materials, stainless steel stands out because it generally holds up for about 10 to 15 years before needing much attention at all. That's quite different from those coated options which usually start showing issues after just 3 to 5 years. Brass is another problem child especially when humidity levels rise, causing it to break down quicker and requiring staff to spend extra time checking and replacing parts. Then there's plastic which doesn't fair well either under constant sun exposure. Over time these plastic pieces tend to bend and twist, sometimes leading to dangerous slips and falls that nobody wants happening anywhere near patients or workers.

Balancing Cost and Durability in High Moisture Environments Like Hospitals and Senior Living

In 24/7 care environments, stainless steel’s longevity and hygienic surface justify its higher initial investment. For budget-sensitive projects, powder-coated aluminum may suffice in low-traffic areas but requires recoating every two years. Some manufacturers now produce hybrid models featuring stainless steel cores with polymer grips, optimizing both performance and cost-efficiency.

Installation Expertise and Building Code Integration Support

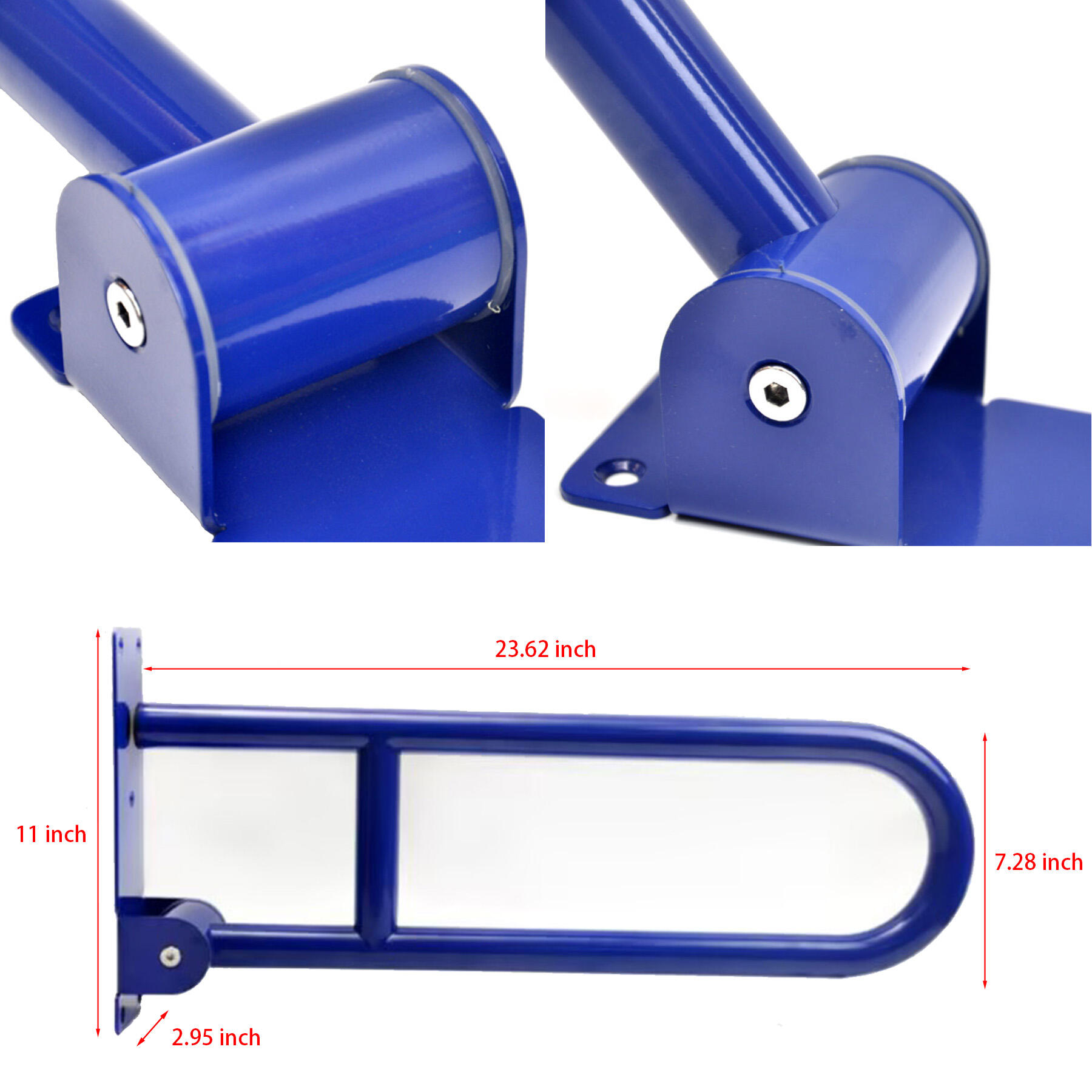

Best Practices for Secure Installation: Stud Placement and Anchoring Systems

Over 82% of grab bar failures in commercial buildings result from incorrect stud alignment, according to a 2023 analysis of hospital safety data. Key best practices include:

- Aligning bars with wall studs spaced 16" or 24" on-center (per ASTM E2357)

- Using 3/16" thick steel mounting plates when stud placement conflicts with ADA height requirements

- Employing heavy-duty toggle bolts (rated for 500+ lbs) for masonry or tiled surfaces

These methods meet both Part 3 and Part 9 of Canadian building codes for sustained and impact loads.

How Top Suppliers Support Contractors in Meeting Local and National Codes

Leading manufacturers facilitate compliance through:

- Pre-assembled compliance kits with validated anchoring components

- Region-specific documentation aligned with local IBC amendments

- On-demand engineering consultations for complex installations

Contractors using digital compliance portals reported a 34% reduction in installation errors compared to those relying on traditional spec sheets, highlighting the value of integrated technical resources—especially when balancing fire codes with accessibility mandates in healthcare settings.

User Centered Design and Supplier Technical Support

Designing for Diverse Populations: Elderly, Disabled, and Post-Surgical Users

Good grab bar designs need to work for people with different physical needs. Many seniors find that bars around 1.5 inches thick are easier on their hands after gripping for long periods. For folks recovering from surgery, installing these bars a bit lower makes all the difference. Instead of the standard 34 inch height, going down to about 32 inches helps prevent those annoying shoulder aches when getting up from a seat. People who have mobility issues tend to prefer grab bars with two distinct textures. One side might be smooth stainless steel so it slides easily during transfers, while the other has a rubber coating that gives better traction when someone needs extra support. These small design choices really matter in making bathrooms accessible for everyone.

Suppliers increasingly offer 3D installation planners based on anthropometric data from the 2023 Human Factors in Assistive Devices Report, enabling accurate simulation of interactions with walkers, wheelchairs, and other mobility aids. This prevents overcrowding and ensures unobstructed access in accessible bathrooms.

Ergonomic Features and Grip Comfort in Safety Grab Bar Selection

Tests on thermoplastic elastomer (TPE) coatings show they cut down slip risks by around 62 percent when surfaces are wet. That's pretty impressive if someone wants safer grip in kitchens or bathrooms. The angled vertical bars we see at 15 to 30 degree tilts actually help keep wrists aligned properly when moving from sitting to standing positions. This design spreads out the pressure across the whole palm area instead of putting all stress on those tiny finger joints. For folks looking at premium options, many products now come with these dual density foam grips. Inside there's a firm layer that gives good structure, while the outside is softer so it doesn't dig into hands during extended use. Makes sense really — nobody wants their palms getting sore after just a few minutes holding onto something.

Technical support teams help match grip styles to user needs: knurled surfaces aid those with limited dexterity, while convex profiles assist arthritic users in maintaining secure holds. This targeted design approach addresses the 27% of bathroom falls linked to inappropriate grip selection in clinical audits.