Toilet flange repair kits help secure where the toilet connects to the drain pipe and stop those nasty sewage leaks from happening. Most kits come with a strong ring made either from plastic or stainless steel plus some stainless steel bolts and seals to fix up broken parts of the flange. The best part? They attach right onto what's already there without tearing up floors or getting into the subfloor area below. That makes them way better than replacing everything entirely. According to recent industry data from PHCC in 2022, around 8 out of 10 plumbers recommend these repair kits when dealing with small flange issues instead of going through the hassle and expense of complete replacement.

Watch for these indicators of flange failure:

According to a 2023 National Association of Home Builders survey, 42% of toilet leaks originate from compromised flanges rather than wax seal failures.

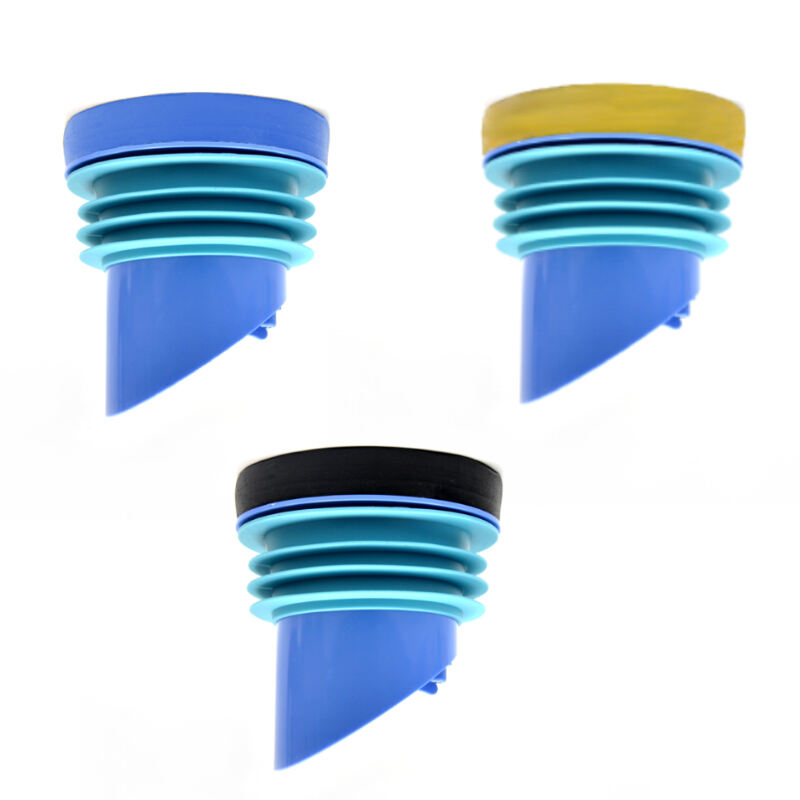

Good quality repair kits form solid mechanical seals thanks to several important components. First there are alignment guides that help get things centered correctly over drainpipes. Then we have bolts made from materials that resist corrosion so they keep holding tight even when temperatures change around them. And finally, compression gaskets that actually conform to those little bumps and irregularities in pipes, working well with gaps as big as quarter inch or so. Kits made with PVC material won't cause electrolytic corrosion problems when paired with copper piping systems. For businesses needing commercial grade solutions, stainless steel versions satisfy all the latest IAPMO standards from 2022. According to PHCC research, most people who install these repair rings right end up stopping leaks about 8 out of 10 times, and this effectiveness lasts decade after decade.

Getting the correct toilet flange repair kit depends first on knowing what kind of pipes run under your floor. Different materials like PVC, ABS plastic, old cast iron, or even lead pipes need their own special approach because they behave so differently when it comes to how stiff they are, how resistant to rust they become over time, and how they expand when heated. Using the wrong type of repair kit might actually make existing leaks worse or cause problems down the road. Take cast iron pipes for instance they work best with those stainless steel reinforcement rings that hold everything together. Meanwhile, most PVC pipes need something called solvent weld to create that tight seal against water escaping through gaps.

Material compatibility ensures long-term stability and prevents recurring issues. PVC repair kits often include adhesives formulated for plastic bonding, whereas cast iron requires rust-resistant fasteners. ABS pipes demand chemical-resistant components to withstand corrosive waste gases. Over 65% of flange leaks stem from incompatible materials, according to a 2023 plumbing systems study.

Working with lead pipes can be quite a headache because they're just so soft and prone to corrosion over time. Regular repair rings often fail to hold properly since they tend to crush rather than grip the pipe surface. Plumbers have found several workarounds for this issue though. Brass reinforcement rings offer better clamping power without damaging the pipe itself. There's also special epoxy putty made specifically for bonding to old lead surfaces that have started to degrade. And when dealing with pipes that are out of alignment or bent from years of stress, offset flange kits come in handy. These specialized tools make all the difference when trying to fix problems in older plumbing systems where replacement isn't always an option.

First things first, get rid of all that oxidation with a good scrubbing using a wire brush and some vinegar mixed up. Once that's cleaned off, apply a slow setting epoxy to patch those gaps where needed. When putting on the repair ring, be gentle with it. Don't go crazy tightening because lead can really bend out of shape when pressed too hard. Let everything sit for at least a full day so the glue has time to set properly before putting the toilet back in place. Most folks find these repairs last anywhere between 8 to maybe even 12 years according to recent plumbing maintenance data from around 2024. Not bad considering how much hassle traditional methods can cause.

Close the water supply valve behind the toilet and flush to empty the tank. Use a sponge to remove remaining water from the bowl, then disconnect the supply line. Loosen the floor bolts with a wrench and carefully lift the toilet straight up to avoid damaging the wax seal or drain pipe. Place it on protective cardboard or towels to prevent surface damage.

Examine the flange for cracks, rust, or misalignment issues linked to 72% of toilet leaks (National Plumbing Association 2023). Clear debris from bolt slots and the drain pipe using a putty knife and wire brush. Check the surrounding subfloor for softness or warping; prolonged moisture exposure may require structural repairs before proceeding.

Position the repair ring over the existing flange, aligning bolt holes at the 3 and 9 o'clock positions. For lead pipes, use a brass repair ring with corrosion-resistant screws. Apply silicone caulk between stacked components if adjusting flange height. Secure the ring to the subfloor using stainless steel screws spaced no more than 4 inches apart for even load distribution.

Place a new wax free seal preferred by 89% of plumbers for easier repositioning onto the flange. Lower the toilet straight down, aligning base holes with the bolts. Tighten nuts alternately in quarter turns until the toilet sits firmly without rocking. As recommended by this old house's stability guidelines, the toilet should bear full weight naturally, without needing forceful downward pressure.

Apply a 1/4-inch bead of mildew resistant silicone caulk around the front and sides of the toilet base, leaving the back unsealed to allow leak detection. Let it cure for 24 hours before use premature exposure reduces sealant effectiveness by 40% (Plumbing Materials Study 2023). Avoid overtightening tank connections, a common cause of post repair leaks.

Excessive torque on mounting bolts is one of the most frequent DIY errors. Plastic repair rings require only 8–10 ft-lbs of torque; exceeding this distorts the flange, compromises the seal, and risks cracking the porcelain base. A 2023 plumbing industry survey found that 42% of DIYers reported cracked flanges due to improper tool use.

Even a 1/8-inch offset between the repair ring and drainpipe can allow sewer gases to escape. Always use a plumbing level to verify horizontal alignment before securing bolts. Adjust the stainless steel collar to match existing bolt patterns precisely so the toilet horn seats fully into the drain pathway.

Water-damaged subfloors contribute to 35% of repeat flange failures, per structural repair data. Probe the surrounding area with an awl—soft or spongy spots indicate rot requiring plywood replacement. Reinforce the area by securing plates (included in premium kits) directly to floor joists using corrosion-resistant screws for optimal support.

A properly installed toilet flange repair kit prevents these issues by creating a stable, watertight connection between the toilet and drainage system.

A well-installed toilet flange repair kit typically delivers 5–10 years of leak-free performance when matched to compatible pipe materials. Longevity depends on installation accuracy, environmental conditions like humidity, and component quality. While repair kits effectively reinforce damaged edges and restore secure bolt alignment, they serve as a secondary support rather than a permanent replacement.

| Factor | Plastic Repair Rings | Stainless Steel Repair Rings |

|---|---|---|

| Corrosion Resistance | Excellent in moist environments | Superior against rust and electrolysis |

| Thermal Tolerance | May warp above 140°F (60°C) | Stable up to 600°F (315°C) |

| Installation Ease | Lightweight; simplifies adjustments | Requires precise alignment |

| Cost | $15–$30 (budget-friendly) | $40–$75 (premium option) |

Plastic kits are ideal for residential applications involving PVC or ABS pipes, offering affordability and chemical stability. Stainless steel is better suited for high-traffic commercial settings where durability under heavy usage and repeated cleaning is essential.

Repair kits are ineffective when facing multiple flange cracks larger than 1/4 inch (6 mm), unstable pipe connections, or advanced subfloor rot. Full replacement is necessary when:

Opt for replacement if floor movement or recurring leaks suggest systemic failure beyond localized damage.