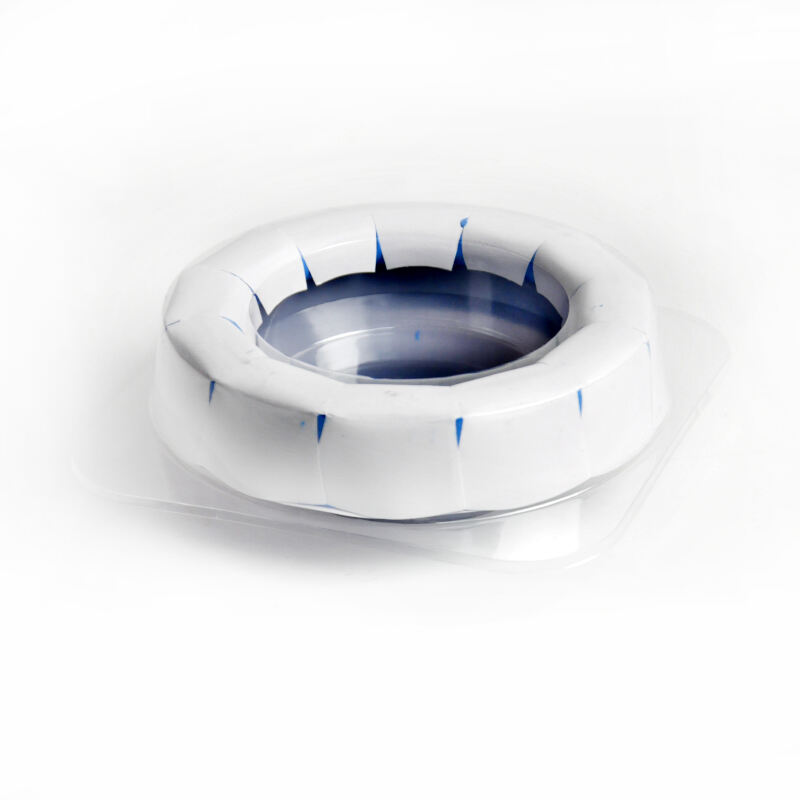

A 70 to 110mm drain seal is a specialized plumbing component designed to create a watertight barrier for drain pipes within this diameter range, commonly used in residential and commercial bathroom, kitchen, and utility room installations. This versatile seal accommodates the most common drain sizes for fixtures such as sinks, showers, bathtubs, and floor drains, providing a flexible solution that adapts to varying pipe dimensions within the specified range. Constructed from durable materials like rubber, silicone, or thermoplastic elastomers, these seals are engineered to withstand constant exposure to water, temperature fluctuations, and chemical cleaners while maintaining their sealing integrity. The design of a 70 to 110mm drain seal typically features a conical or cylindrical shape with a flexible lip that compresses against the pipe and surrounding fixture, creating a tight seal that prevents water leakage and the escape of sewer gases. Many models include a flange or mounting ring that secures the seal in place, ensuring it remains properly positioned during and after installation. This is particularly important for floor drains or shower bases, where movement or shifting could compromise the seal. Installation of a 70 to 110mm drain seal involves placing the component between the fixture outlet and the drain pipe, ensuring a snug fit that allows for minor adjustments to accommodate slight variations in pipe diameter. The flexibility of the materials used allows the seal to conform to irregular surfaces, filling gaps that could lead to leaks. For rigid pipe connections, some seals feature ribbed interiors that enhance grip and prevent slippage, while others use adhesive backing or compression fittings for added security. In bathroom applications, these seals are essential for preventing water damage to subfloors and surrounding structures, especially in wet areas like showers and bathtubs where standing water is common. They are also resistant to mold and mildew growth, maintaining hygiene in damp environments. Commercial settings, such as hotels and public facilities, benefit from the durability of these seals, which can withstand heavy usage and frequent cleaning. When selecting a 70 to 110mm drain seal, compatibility with both the fixture and pipe material (PVC, ABS, copper, or cast iron) is crucial. Temperature resistance is another key consideration, as seals in hot water systems must withstand higher temperatures without degrading. Many manufacturers provide specifications regarding maximum temperature and pressure ratings, ensuring proper selection for specific applications. Regular inspection and maintenance of these seals, including checking for cracks, hardening, or displacement, help prevent leaks and extend their lifespan. Replacement is straightforward, typically requiring only basic tools and minimal disruption to the plumbing system. By providing a reliable, adaptable sealing solution for common drain sizes, 70 to 110mm drain seals play a vital role in maintaining the functionality and integrity of plumbing systems in both residential and commercial buildings.