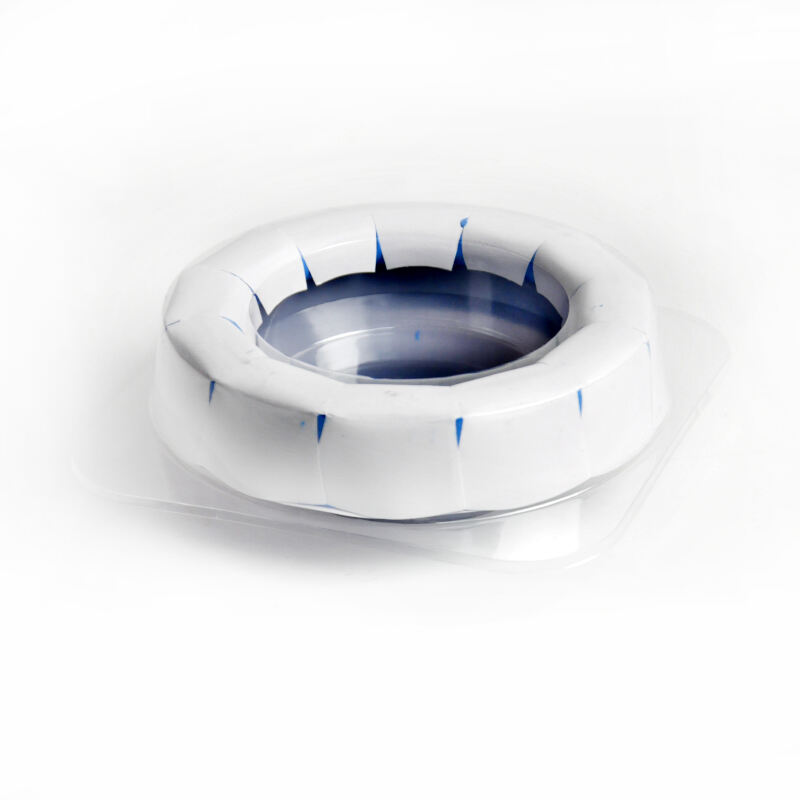

A rubber toilet wax ring, often referred to as a wax free toilet seal, is a modern plumbing innovation that replaces traditional petroleum based wax with durable, flexible rubber materials to create a reliable seal between the toilet bowl and the floor flange. This advanced sealing solution offers a range of benefits over conventional wax rings, including enhanced durability, easier installation, and superior performance in challenging environmental conditions. Constructed from high grade elastomers or synthetic rubber compounds—often reinforced with rigid plastic cores or metal rings—rubber toilet wax rings are engineered to compress uniformly when the toilet is installed, forming a tight, custom fit that adapts to minor imperfections in the flange or toilet base. Unlike wax, which can degrade over time, rubber maintains its elasticity and sealing properties for extended periods, ensuring long term reliability even in humid bathrooms or areas with temperature fluctuations. The design of a rubber toilet wax ring typically features a circular base that sits on the flange, with a central sleeve or horn that extends into the drain pipe to prevent leaks at the critical connection point. Many models incorporate multiple sealing lips or ribs that create redundant barriers against water and gas, ensuring that even if one seal is compromised, others maintain protection. Some rubber rings also include a self adhesive backing that secures the seal in place during installation, reducing the risk of shifting that can lead to leaks. Installation of a rubber toilet wax ring is significantly cleaner and more straightforward than working with traditional wax. There is no mess from crumbled wax, and the rubber material is easy to handle and position correctly. The ring is placed on the flange, aligned with the drain opening, and the toilet is lowered into position. The weight of the toilet compresses the rubber, creating an immediate, effective seal that requires no curing time. This simplicity makes rubber rings ideal for DIY installations, as they reduce the risk of improper sealing due to uneven wax compression. Rubber toilet wax rings are compatible with most standard toilet models and flange materials, including PVC, cast iron, and brass. They are resistant to water, chemicals, and microbial growth, ensuring hygiene and performance in both residential and commercial settings. Unlike wax rings, which must be replaced every time the toilet is removed, rubber rings can often be reused if carefully inspected and cleaned, reducing waste and long term costs. In high use environments such as hotels, schools, and office buildings, rubber rings offer enhanced durability, minimizing the need for frequent replacements and reducing maintenance expenses.