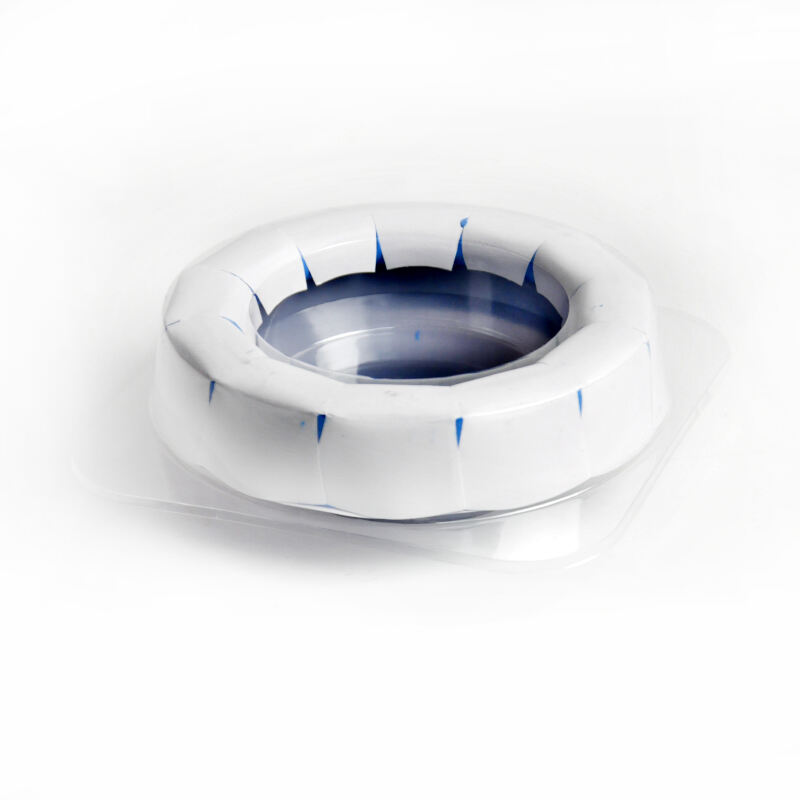

A custom toilet wax ring is a specialized sealing solution engineered to address unique or non standard toilet installation challenges, providing tailored sealing performance for situations where standard wax rings may fail to create a secure, leak free connection. These bespoke rings are designed to accommodate irregularities such as non standard flange sizes, significant gaps between the toilet base and flange, unusual drain configurations, or compatibility issues with specialty toilets, ensuring effective sealing in residential, commercial, or industrial settings where off the shelf solutions are insufficient. The customization of these wax rings can take several forms, starting with material composition. Manufacturers may adjust the wax blend—varying the ratio of petroleum waxes, microcrystalline waxes, and additives—to achieve specific properties such as increased flexibility for uneven surfaces, enhanced rigidity for high pressure applications, or improved chemical resistance for commercial environments using aggressive cleaning agents. Some custom rings incorporate reinforcing materials like fiberglass mesh or metal shims to add structural support, preventing compression beyond a certain point and maintaining the seal even under heavy toilet weight or frequent use. Size customization is another key feature of custom toilet wax rings. While standard rings fit 3 inch and 4 inch drains, custom versions can be produced in diameters ranging from 2 inches for compact toilets to 6 inches for oversized commercial fixtures. Thickness is also adjustable, with extra thick rings (up to 2 inches) designed to bridge gaps where the flange sits significantly below the floor level—a common issue in older homes with floor renovations or uneven subfloors. For toilets with offset drains or non circular base patterns, custom shaped wax rings with contoured edges ensure complete coverage of the flange opening, eliminating potential leak points. Design modifications further distinguish custom wax rings. Some include extended plastic horns with flexible collars to accommodate misaligned drains, allowing up to 1.5 inches of horizontal or vertical adjustment between the toilet outlet and flange. Others feature integrated gaskets made from rubber or silicone that combine the conformability of wax with the elasticity of synthetic materials, creating a dual seal system that enhances reliability. For wall hung toilets, custom wax rings may include metal backing plates or mounting hardware that integrate with the toilet’s suspension system, ensuring the seal remains intact under the fixture’s weight. Custom toilet wax rings are particularly valuable in retrofit projects, heritage building restorations, or installations using imported or specialty toilets with non standard dimensions. They address the limitations of standard products, which may fail to seal properly in non ideal conditions, leading to leaks, water damage, or persistent odors. By working with manufacturers to specify exact dimensions, material properties, and design features, plumbers and contractors can ensure a perfect seal that meets the unique demands of each installation. While custom rings may involve longer lead times and higher costs than standard versions, their ability to solve complex sealing challenges ultimately reduces long term maintenance expenses and ensures compliance with plumbing codes and standards.