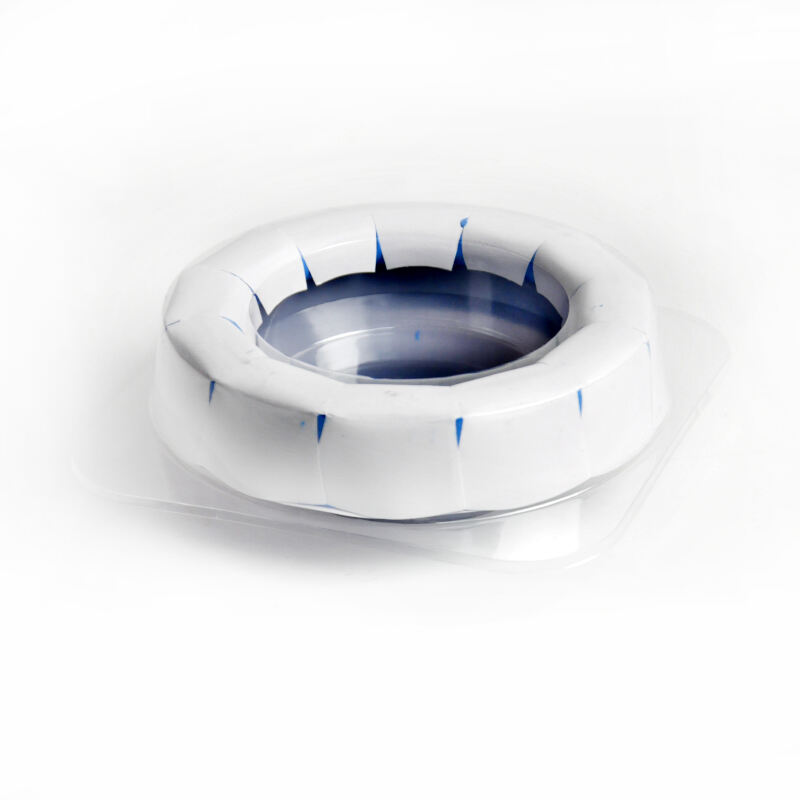

Installing a double wax ring on a toilet is a specialized plumbing technique used to address specific installation challenges, involving the use of two stacked wax rings to create an enhanced seal between the toilet bowl and the floor drain flange. This method is typically employed when the floor flange sits significantly below the finished floor level—usually more than 1/4 inch—a common issue in older homes with floor renovations, uneven subfloors, or when replacing a toilet with a different base height that creates a larger gap between the fixture and the flange. By doubling the wax material, this approach provides sufficient compression to bridge the increased gap, ensuring a watertight and gas tight seal that a single wax ring might fail to achieve. Each wax ring in the double setup contributes to the sealing process, with the bottom ring compressing against the flange and the top ring forming a seal against the toilet base. The combined thickness of two rings—typically 1 to 1.5 inches—allows for adequate compression even when the flange is recessed, preventing gaps that could lead to leaks. When using a double wax ring, it is crucial to select rings of compatible design, often avoiding models with large horns in both rings to prevent interference. Instead, plumbers may use one ring with a horn for the drain pipe seal and a flat ring for the base seal, or two flat rings, depending on the specific installation needs. The rings are stacked carefully on the flange, aligned to center over the drain opening, before the toilet is lowered into place. Proper installation technique is essential when using a double wax ring to avoid common pitfalls. The toilet must be lowered straight down onto the stacked rings without rocking or twisting, ensuring even compression of both rings. Uneven pressure can cause one ring to compress more than the other, creating gaps in the seal. The toilet bolts should be tightened gradually and evenly to distribute pressure, preventing cracking of the porcelain base while ensuring sufficient compression of the wax. It is also important to verify that the total height of the stacked rings does not exceed the gap between the toilet base and the flange, as excessive wax can extrude into the drain line or create an unstable base for the toilet. Double wax rings are particularly useful in situations where raising the flange to floor level is not feasible due to structural constraints or cost considerations. They provide a practical solution for DIY homeowners and professional plumbers alike, allowing for a secure seal without major plumbing modifications. In commercial settings, where floor conditions may vary and heavy use toilets require reliable sealing, double wax rings offer an added layer of protection against leaks and sewer gas emissions. However, it is important to note that double wax rings should be used selectively, as unnecessary stacking can lead to problems such as uneven seating of the toilet or wax extrusion into the drain. Plumbers typically recommend this method only when the flange is significantly below floor level, relying on standard single rings for most installations. When applied correctly, double wax rings provide a robust, cost effective solution for challenging toilet installations, ensuring long term reliability and preventing water damage in both residential and commercial bathrooms.