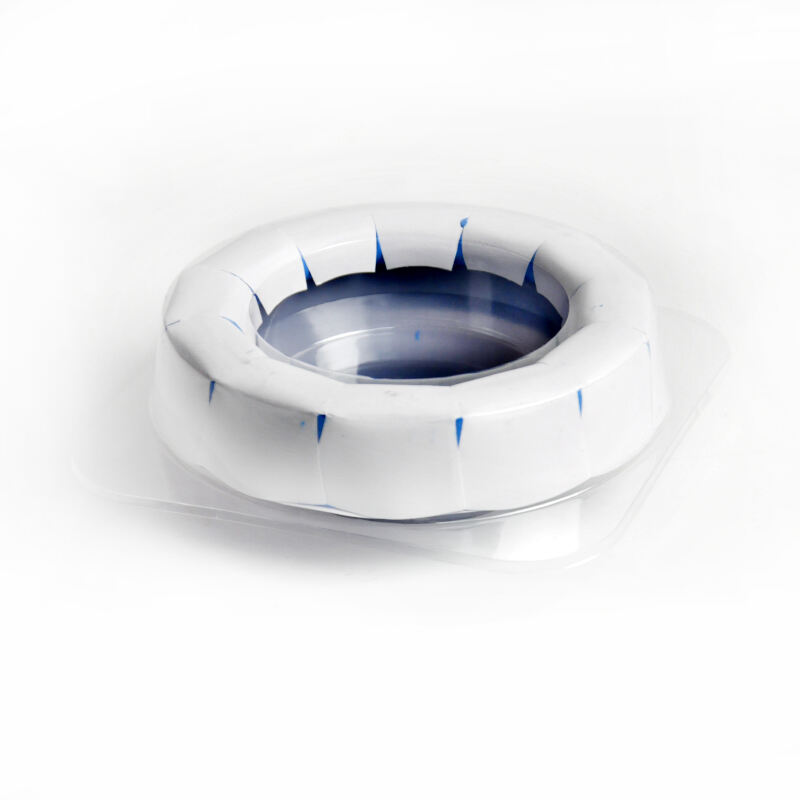

A plumbing sealant for toilet is a specialized adhesive and sealing compound designed to enhance the watertight and gas tight integrity of toilet installations, complementing or in some cases replacing traditional wax rings or rubber seals. Formulated for use in wet environments, these sealants create a flexible, durable bond between the toilet base and floor flange, as well as around other toilet components such as water supply connections and tank to bowl joints, preventing leaks and ensuring long term plumbing reliability. Available in various forms including silicone based, polyurethane, and acrylic latex sealants, each type offers specific properties tailored to different toilet sealing applications. Silicone based plumbing sealants are particularly popular for toilet installations due to their exceptional water resistance, flexibility, and adhesion to non porous surfaces like porcelain, PVC, and metal. They remain flexible over time, accommodating minor movements of the toilet or flange without cracking, which is crucial for preventing leaks in bathrooms where floor settling or temperature changes can cause slight shifts. Silicone sealants also resist mold and mildew growth, maintaining a hygienic seal in humid environments. Polyurethane sealants offer superior strength and durability, making them suitable for heavy duty applications or where a more rigid seal is required, while acrylic latex sealants provide easier cleanup and are often paintable, though they may require more frequent reapplication in high moisture areas. When used with traditional wax rings or rubber seals, plumbing sealant for toilet adds an extra layer of protection by sealing any potential gaps around the perimeter of the primary seal. It can also be used to seal the base of the toilet to the floor, preventing water from seeping under the fixture from spills or condensation. For water supply connections, a thread sealing plumbing sealant or tape combined with sealant ensures a leak free connection between the supply line and toilet tank. Application requires proper surface preparation: the flange and toilet base must be clean, dry, and free of old sealant residue or debris. The sealant is applied in a continuous bead along the flange or toilet base, and the toilet is positioned and secured before the sealant cures. Most