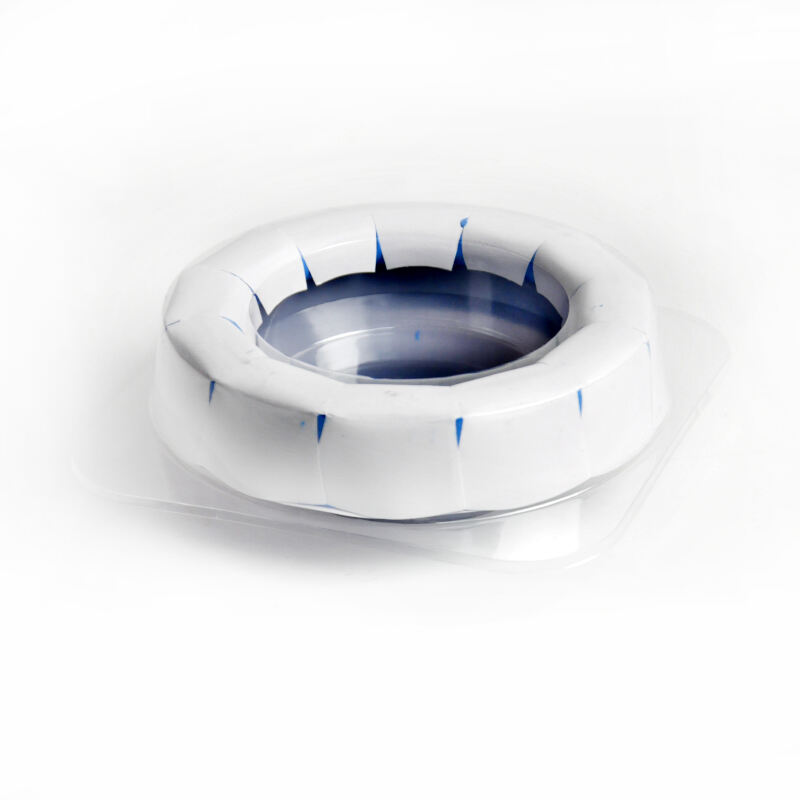

A toilet flange wax ring is a critical plumbing component designed to create a watertight and gas tight seal between the toilet bowl and the floor mounted flange, serving as the primary barrier against water leakage, sewer gas emissions, and odor infiltration in residential and commercial bathrooms. Specifically engineered to interface with the flange— the circular pipe fitting that connects the toilet to the drain line—this wax ring is tailored to accommodate the flange’s dimensions and mounting configuration, ensuring a precise seal that adapts to both components’ unique contours. Constructed from a specialized blend of petroleum based waxes, microcrystalline waxes, and reinforcing materials like fiber mesh or a plastic core, the toilet flange wax ring balances malleability and structural integrity. The wax compound is formulated to compress uniformly when the toilet is installed, filling micro gaps between the flange’s top surface and the toilet’s base while resisting extrusion into the drain pipe. Most models feature a central, cone shaped horn that extends into the flange’s drain opening, enhancing the seal at this critical junction and preventing wax from entering the plumbing system, which could cause clogs. The ring’s outer diameter matches standard flange sizes typically 3 or 4 inches—ensuring complete coverage of the flange’s opening. Installation requires positioning the wax ring precisely on the flange, aligning it with the drain hole and mounting bolt holes to avoid interference with securing the toilet. The toilet is then lowered onto the ring, with its weight compressing the wax to form a custom seal that conforms to any minor irregularities in the flange or toilet base. Proper compression is achieved by tightening the toilet bolts gradually, distributing pressure evenly to prevent uneven sealing or porcelain damage. Toilet flange wax rings are compatible with various flange materials, including PVC, cast iron, and brass, making them versatile for different plumbing systems. They perform effectively in both new installations and replacements, adapting to flange heights that are flush with or slightly below the floor level (though excessively recessed flanges may require extra thick rings). Regular inspection for signs of wax degradation such as water pooling around the base, musty odors, or a loose toilet ensures timely replacement, typically every 5 to 10 years depending on usage and environmental conditions. By creating a reliable seal between the toilet and flange, this component protects against water damage to subfloors and flooring, maintains indoor air quality by blocking sewer gases, and ensures the long term functionality of the toilet system.