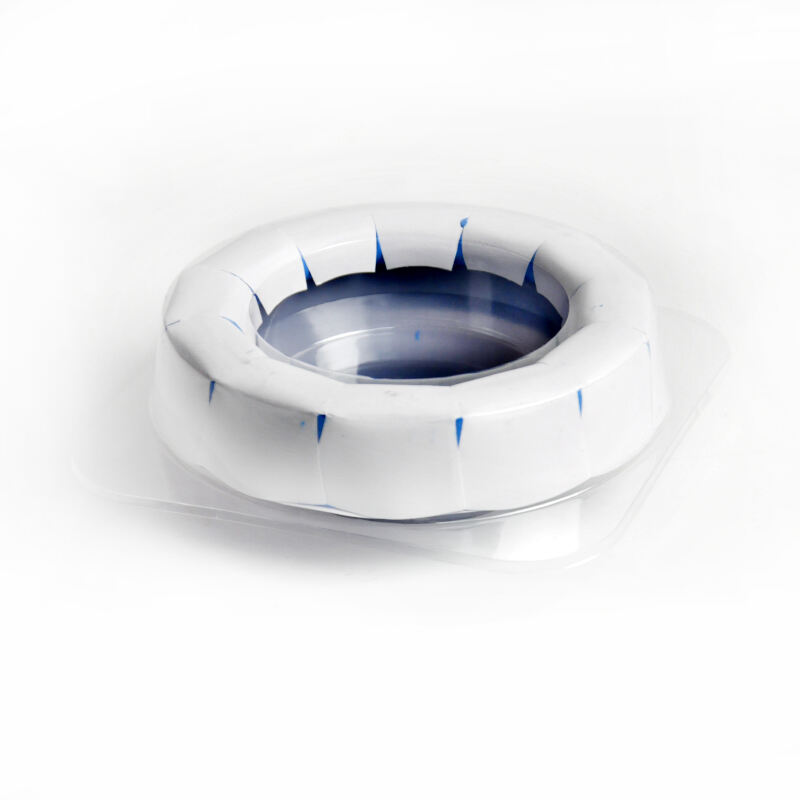

A toilet seal wax ring is a fundamental plumbing component that serves as the primary barrier between a toilet bowl and the floor drain flange, creating an impermeable seal to prevent water leakage, sewer gas escape, and odor infiltration in residential and commercial bathrooms. This essential fixture, composed of a malleable wax compound combined with reinforcing materials, has been a staple in plumbing installations for decades, valued for its ability to conform to irregular surfaces and create a custom seal that adapts to the unique contours of each toilet and flange connection. The composition of a toilet seal wax ring typically includes a blend of petroleum waxes, microcrystalline waxes, and sometimes beeswax, which together provide the ideal balance of flexibility and rigidity. This mixture allows the ring to compress when the toilet is bolted down, filling gaps as small as 1/8 inch between the toilet base and flange, while maintaining enough structure to resist crumbling or washing away over time. Many modern wax rings incorporate a plastic or rubber core, often referred to as a "horn," which extends into the drain pipe to enhance the seal and prevent wax from entering the plumbing system during installation. Some models also feature a polyethylene flange or adhesive backing to facilitate proper positioning and prevent shifting during toilet placement. Installation of a toilet seal wax ring requires careful preparation to ensure optimal performance. The flange must be clean and free of debris, old wax residue, or corrosion, as contaminants can compromise the seal. The wax ring is centered on the flange, with the horn (if present) inserted into the drain opening, and the toilet is then lowered onto the ring, applying even pressure to compress the wax uniformly. The toilet bolts are tightened gradually to avoid cracking the porcelain base while ensuring sufficient compression—typically 20 to 30 pounds of force—to activate the wax’s sealing properties. This process creates a permanent, water tight bond that remains effective even as the toilet shifts slightly over time due to normal use or floor movement. Toilet seal wax rings are available in various sizes to accommodate standard drain configurations, with 3 inch and 4 inch diameter options being most common for residential and commercial toilets, respectively. They are compatible with all types of toilet flanges, including cast iron, PVC, and brass, and work effectively with both floor mounted and wall hung toilets (when paired with appropriate mounting hardware). In situations where the flange sits below the floor level, "extra thick" wax rings or stacked wax rings provide additional material to bridge the gap and maintain a proper seal. While alternative sealing products like rubber gaskets exist, wax rings remain a preferred choice for many plumbers due to their reliability, cost effectiveness, and versatility. They perform well in extreme temperature conditions, resist degradation from cleaning chemicals, and require no special tools for installation. By creating an impenetrable barrier between the toilet and the sewer system, a properly installed toilet seal wax ring protects against water damage to floors and subfloors, prevents the spread of harmful sewer gases, and ensures a hygienic, odor free bathroom environment for years to come.