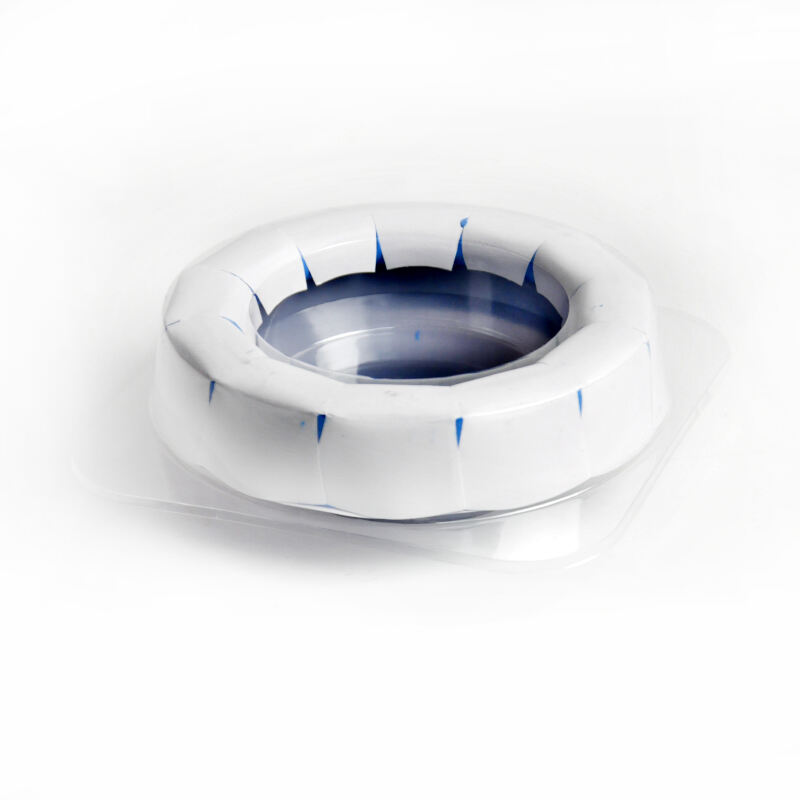

A toilet sealing ring is an essential component in toilet installation and maintenance, serving as a critical barrier to prevent water leakage, gas emissions, and the spread of unpleasant odors from the sewer line into the bathroom. This small but vital part is positioned between the toilet bowl and the floor flange, creating a tight and secure seal that ensures the proper functioning of the toilet system. Toilet sealing rings are available in various materials, including traditional wax, flexible rubber, and durable high elastic polymer, each offering unique advantages to suit different applications and user needs. Traditional wax rings, composed of a mixture of beeswax or paraffin wax and other additives, have been a staple in the industry for decades. They are known for their ability to conform to irregular surfaces, creating a reliable seal when compressed between the toilet bowl and the flange. Wax rings are cost effective and work well in standard installations, but they can become brittle over time, especially in environments with fluctuating temperatures, which may lead to leaks. They also require careful handling during installation to avoid breaking or misshaping, which could compromise the seal. Rubber toilet sealing rings have gained popularity as a modern alternative to wax rings. Made from high quality, flexible rubber, these rings offer superior durability and resistance to water, temperature changes, and degradation. Their flexibility allows them to maintain a tight seal even with minor movements of the toilet bowl, reducing the risk of leaks. Rubber rings are also easier to install and remove, as they do not crumble like wax, making them a preferred choice for both professional plumbers and DIY enthusiasts. Additionally, they are often reusable if removed carefully, adding to their cost effectiveness over time. High elastic polymer sealing rings represent the latest innovation in this category. These rings are crafted from advanced polymer materials that combine elasticity with exceptional strength, providing a long lasting seal that can withstand heavy use and harsh conditions. They offer 360 degree protection against leaks, odors, bacteria, and pests, making them ideal for commercial settings such as hotels, hospitals, and apartment buildings. High elastic polymer rings are resistant to chemicals commonly found in cleaning products, ensuring their performance remains uncompromised even with regular maintenance. The choice of toilet sealing ring depends on factors such as the installation environment, budget, and specific requirements. For residential use, rubber or wax rings may be sufficient, while commercial applications often benefit from the enhanced durability of high elastic polymer rings. Regardless of the material, proper installation is crucial to ensure the ring functions effectively. This involves cleaning the flange and toilet base thoroughly, positioning the ring correctly, and securing the toilet bowl tightly to compress the ring evenly. Toilet sealing rings may seem like a small component, but their role in maintaining the hygiene, functionality, and safety of a bathroom cannot be overstated. A properly functioning sealing ring prevents water damage to floors and subfloors, avoids the spread of sewer gases and odors, and contributes to a healthier living or working environment. By selecting the right type of sealing ring and ensuring it is installed correctly, homeowners and facility managers can ensure the long term performance of their toilet systems.