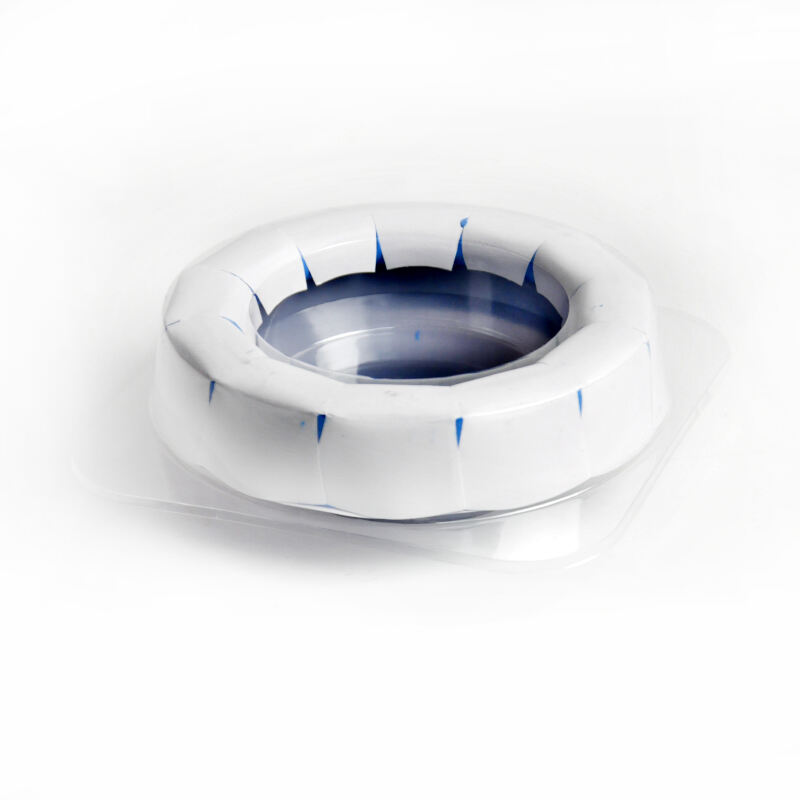

A urinal wax ring is a specialized sealing component designed to create a watertight and gas tight barrier between a urinal fixture and its corresponding drain flange, preventing leaks, sewer gas emissions, and odor propagation in restroom facilities. Specifically engineered for the unique installation requirements of urinals—whether wall mounted, floor mounted, or trough style—these wax rings address the distinct plumbing configurations and usage demands of commercial and institutional restrooms, where urinals experience high traffic and frequent use. Composed of a blend of petroleum based waxes, synthetic polymers, and reinforcing materials, urinal wax rings are formulated to withstand the specific conditions of urinal installations, including exposure to varying water pressure, cleaning chemicals, and temperature fluctuations. The wax mixture is firmer than that used in toilet wax rings to accommodate the vertical or angled drain connections common in urinal designs, ensuring it maintains its shape during installation while still providing sufficient compression to create a secure seal. Many models include a rigid plastic or metal core that adds structural stability, preventing deformation under the weight of the urinal or during cleaning procedures. The design of urinal wax rings varies based on the type of urinal they serve. For wall mounted urinals, which are suspended above the floor, the wax ring is typically smaller in diameter but features an extended neck or horn that fits precisely into the drain pipe, creating a seal that accommodates the downward slope of the fixture. Floor mounted urinal wax rings, by contrast, are often larger and flatter, resembling toilet wax rings but sized to match the wider base flanges of floor standing models. Trough urinal systems may use specialized wax rings with elongated shapes to seal multiple drain points along the trough’s length. Installation of a urinal wax ring requires careful alignment to ensure proper sealing. The ring is placed on the drain flange, and the urinal is lowered or positioned into place, compressing the wax to form a custom seal around the connection. The firmness of the wax prevents extrusion into the drain line, which could cause clogs, while its flexibility allows it to adapt to minor irregularities in the flange or fixture base. Many commercial grade urinal wax rings are compatible with both metal and PVC drain pipes, offering versatility across different plumbing systems. In high usage environments such as airports, stadiums, schools, and office buildings, the durability of urinal wax rings is critical. Premium models are designed to maintain their sealing integrity for 5 to 10 years under heavy use, resisting degradation from harsh cleaning agents like bleach and disinfectants commonly used in restroom maintenance. They also prevent the ingress of debris into the drain line, reducing the risk of blockages that could lead to overflows and water damage. Compliance with plumbing standards is essential for urinal wax rings, as improper sealing can result in costly water damage, unsanitary conditions, and code violations. Reputable manufacturers ensure their products meet specifications outlined by organizations such as the International Plumbing Code (IPC) and ASTM International, guaranteeing compatibility with standard drain sizes (typically 2 to 3 inches for urinals) and performance under specified pressure and temperature conditions. By providing reliable, long lasting seals, urinal wax rings contribute to the overall functionality, hygiene, and cost effectiveness of commercial restroom operations.