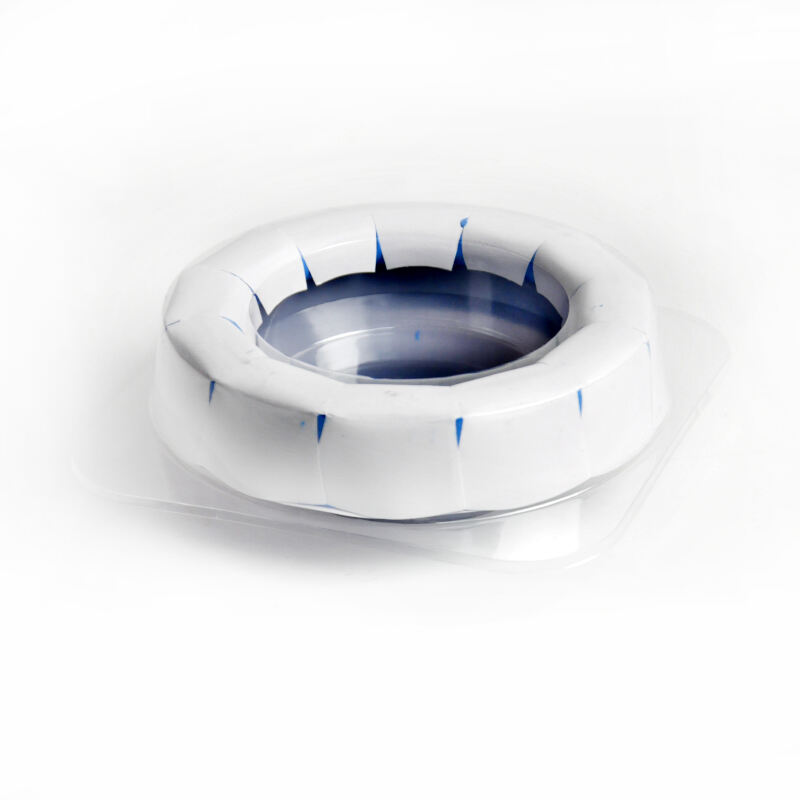

A toilet wax pan seal ring is a specialized plumbing component designed to create a comprehensive watertight and gas tight seal between the base of a toilet and the floor drain flange, with a design that extends the sealing surface to cover the entire perimeter of the toilet’s base, often referred to as the "pan." This expanded sealing area provides enhanced protection against leaks, making it particularly valuable in installations where the flange is damaged, uneven, or where a more robust seal is required for heavy use environments. Unlike standard wax rings that focus on sealing the immediate area around the drain opening, the wax pan seal ring features a broader, flatter wax disc that extends outward to match the footprint of the toilet’s base. This larger surface area ensures that any minor gaps between the toilet and the floor are sealed, preventing water from seeping under the fixture—whether from condensation, overflow, or minor leaks at the drain connection. The wax used in these rings is typically denser and more malleable, formulated to compress uniformly across the entire pan area while maintaining sufficient rigidity to support the toilet’s weight without excessive deformation. Construction of a toilet wax pan seal ring involves a blend of high quality waxes, often including microcrystalline wax for flexibility and petroleum wax for durability, combined with reinforcing materials like fiber mesh or a plastic core to prevent tearing during installation. Some models incorporate a rubberized border around the perimeter of the wax disc, enhancing the seal against uneven floor surfaces and providing additional resistance to water penetration. The central portion of the ring may include a raised horn or sleeve to seal the drain pipe connection, combining the benefits of a standard wax ring with the expanded protection of the pan seal. Installation of a wax pan seal ring requires careful positioning to ensure full contact between the wax and both the toilet base and the floor flange. The ring is placed on the flange, aligned to cover the entire drain opening and extend to the edges of the toilet’s base footprint. When the toilet is lowered into place, the weight of the fixture compresses the wax evenly across the entire pan area, creating a continuous seal that prevents water migration. This design is especially advantageous for toilets installed on uneven floors, over vinyl or linoleum flooring that may shift slightly, or in basements and bathrooms where water damage could have significant consequences. In commercial settings such as hotels, hospitals, and public restrooms, where toilet usage is frequent and the risk of overflow is higher, wax pan seal rings are preferred for their enhanced leak protection. They provide an extra layer of security against the wear and tear of constant use, reducing the need for frequent maintenance and minimizing the risk of water damage to subfloors and surrounding structures. Homeowners with older homes or those who have experienced previous leaks may also opt for wax pan seal rings to ensure a more reliable, long lasting seal. While these rings may be slightly thicker and heavier than standard wax rings, their ability to create a comprehensive seal across the entire toilet base makes them a valuable investment for anyone seeking maximum protection against water damage and sewer gas infiltration in their bathroom plumbing system.