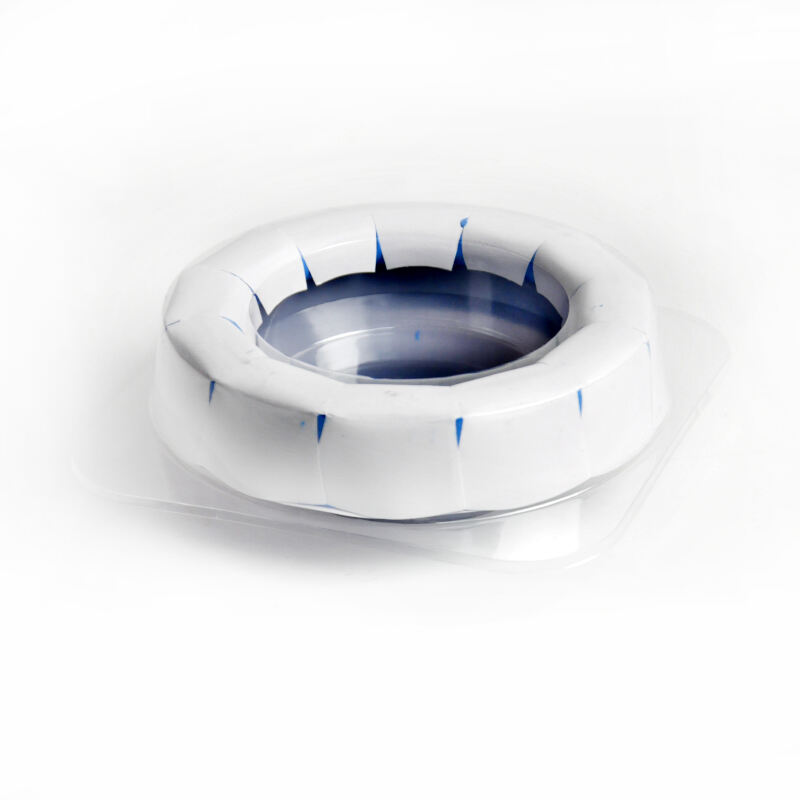

A wax ring for toilet installation is an essential component that creates a critical seal between the toilet bowl and the floor flange, ensuring a watertight and gas tight connection that prevents leaks, sewer gas emissions, and odor infiltration. During the initial installation of a new toilet or the replacement of an existing fixture, selecting the right wax ring and installing it properly is fundamental to the long term functionality and reliability of the plumbing system. The wax ring serves as the primary barrier between the toilet’s outlet and the drain pipe, adapting to the unique contours of both surfaces to create a custom seal that cannot be achieved with rigid materials alone. Wax rings designed for toilet installation are typically composed of a blend of petroleum based waxes, microcrystalline waxes, and reinforcing materials such as fiber mesh or a plastic core. This composition provides the ideal balance of malleability and structural integrity: the wax is soft enough to compress when the toilet is installed, filling any gaps or irregularities, yet firm enough to maintain its shape under the weight of the toilet and resist extrusion into the drain pipe. Many wax rings feature a raised central horn or sleeve that extends into the drain opening, enhancing the seal at the critical connection point where the toilet’s outlet meets the pipe. For standard installations, a single wax ring of moderate thickness (usually ½ to ¾ inch) is sufficient when the flange is flush with or slightly above the finished floor. In situations where the flange sits below the floor level, extra thick wax rings or stacked rings may be necessary to bridge the gap and ensure proper compression. Some installations, particularly those in commercial settings or with heavy use toilets, may utilize wax rings with integrated plastic flanges that provide additional stability and alignment assistance. Proper installation technique is crucial for maximizing the effectiveness of the wax ring. The flange must be clean, level, and in good condition before placing the wax ring. The ring is centered on the flange, with the horn (if present) pointing upward into the drain pipe. The toilet is then carefully lowered straight down onto the ring, ensuring even contact without rocking or twisting, which could displace the wax and create leaks. Once the toilet is in position, the mounting bolts are tightened gradually and evenly to compress the wax uniformly, creating a secure seal. It is important to avoid over tightening the bolts, as this can crack the toilet base or distort the flange. After installation, allowing the wax to set under the weight of the toilet for a short period before connecting the water supply ensures the seal is fully formed. Testing for leaks by flushing the toilet and inspecting the base for water accumulation is the final step in verifying a successful installation. By selecting a high quality wax ring appropriate for the specific installation conditions and following proper installation procedures, homeowners and plumbers can ensure a reliable, long lasting seal that protects against water damage, maintains indoor air quality, and ensures the proper functioning of the toilet for years to come.