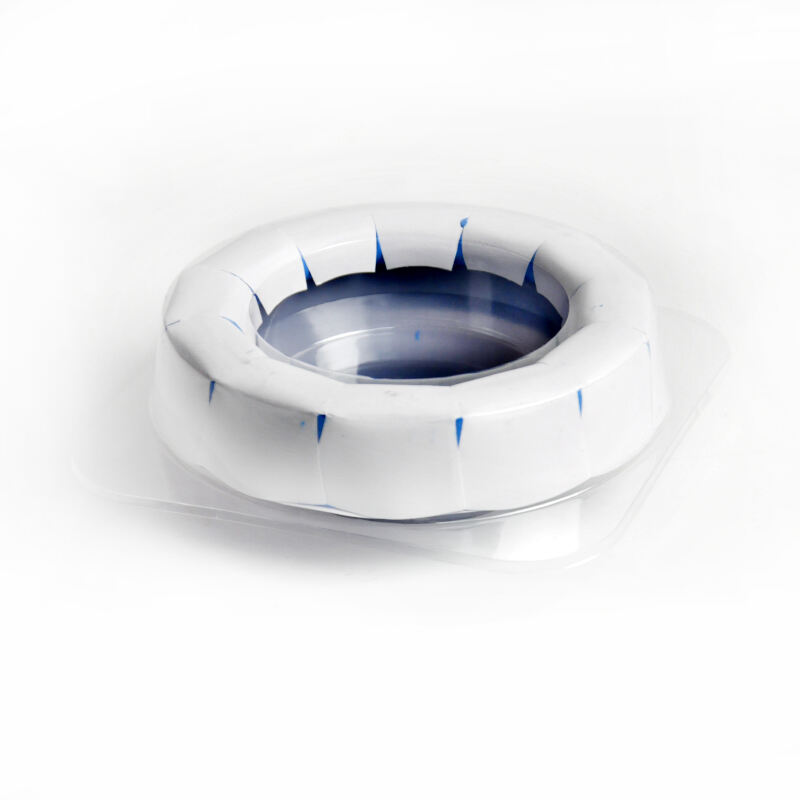

A wall hung toilet wax ring is a specialized sealing component designed exclusively for the unique installation requirements of wall-mounted toilets, creating a watertight and gas-tight barrier between the toilet’s outlet and the concealed drain flange located within the wall. Unlike floor-mounted toilets, which connect to a flange at floor level, wall hung toilets are suspended from a carrier system installed inside the wall, requiring a wax ring that accommodates the horizontal or angled drain connection and the specific clearance constraints of hidden plumbing systems. Constructed from a high-performance blend of waxes and reinforcing materials, these rings are engineered to address the vertical and horizontal forces exerted by wall-mounted fixtures, ensuring a secure seal even with the weight of the toilet and user supported by the wall structure. The wax mixture typically includes microcrystalline waxes for enhanced flexibility and petroleum waxes for structural stability, combined with a rigid plastic or metal core that prevents deformation under pressure. This core also helps maintain the ring’s shape during installation, which is critical in tight wall cavities where access is limited. Many wall hung toilet wax rings feature a contoured design with a flared base that matches the outlet of wall-mounted toilets, which often have a shorter, more angled discharge pipe compared to floor models. This tailored shape ensures maximum contact between the ring and both the toilet outlet and the wall flange, eliminating gaps that could lead to leaks. Some models include a rubberized outer layer that enhances adhesion to smooth surfaces like PVC or copper pipes, providing an extra layer of protection against water seepage. Installation of a wall hung toilet wax ring requires precision due to the concealed nature of the plumbing. The ring must be positioned correctly on the toilet’s outlet before mounting the fixture to the wall carrier, as access to the seal is limited once the toilet is secured. The carrier system’s alignment is critical, as any misalignment can cause uneven compression of the wax ring. Many professional installers recommend dry-fitting the toilet without the ring first to verify alignment, then installing the ring and securing the toilet with the appropriate hardware—typically bolts that fasten to the wall carrier. This process ensures even compression of the wax, activating the seal. Wall hung toilet wax rings are also designed to withstand the unique environmental conditions of wall cavities, which may have limited ventilation and higher humidity. The materials resist mold and mildew growth, ensuring long-term performance without degradation. They are compatible with standard wall flange sizes (usually 3 or 4 inches) and work with most wall-mounted toilet models from major manufacturers. In commercial settings such as restaurants, hotels, and office buildings, where wall hung toilets are popular for easy cleaning, these wax rings offer reliable performance under heavy usage. They are also valued in residential applications for their space-saving benefits and sleek design, with the wax ring playing an unseen but vital role in maintaining functionality. While installation is more technically demanding than floor-mounted toilets, the specialized design of wall hung toilet wax rings ensures that, when properly installed, they provide the same level of leak protection and durability, making them an essential component in modern wall-mounted plumbing systems.