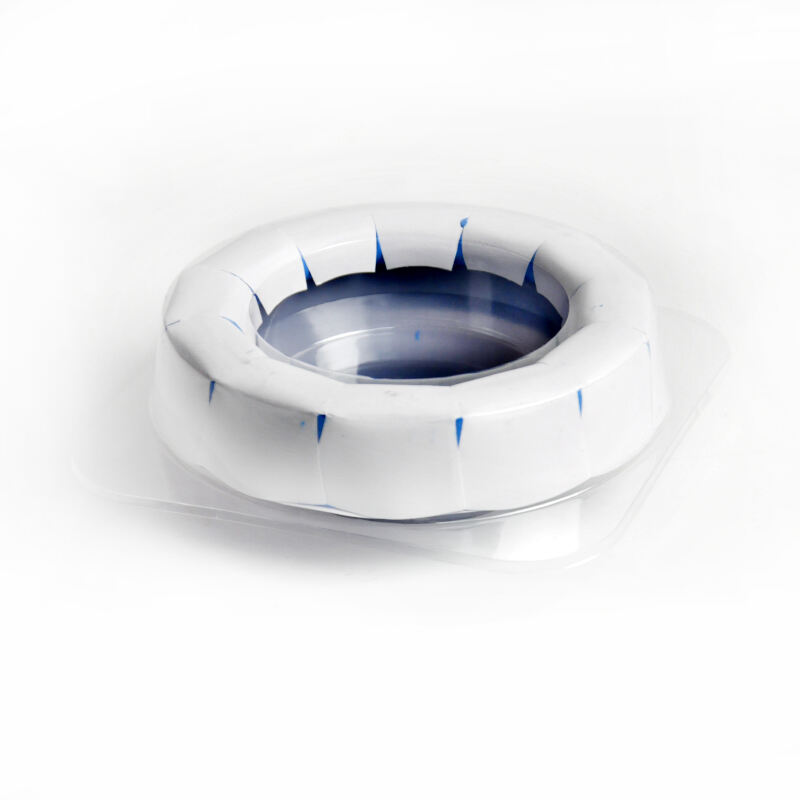

A wax ring with horn is a specialized plumbing component designed to enhance the sealing performance between a toilet bowl and the floor drain flange, incorporating a raised, cone shaped extension (the "horn") that serves as an additional barrier against leaks and sewer gas infiltration. This innovative design builds upon the traditional wax ring by adding a structural element that targets the critical connection point where the toilet’s outlet pipe meets the drain line, providing enhanced protection in both residential and commercial installations. The horn, typically made from rigid plastic or rubber, is integrally molded or attached to the center of the wax ring, extending upward to fit snugly into the toilet’s outlet opening. When the toilet is installed, this horn creates a secondary seal within the pipe itself, complementing the primary seal formed by the compressed wax around the flange. This dual seal mechanism significantly reduces the risk of water leakage, especially in situations where the flange is slightly misaligned or the wax compression is uneven. The horn also prevents wax from extruding into the drain line during installation, which could cause clogs or reduce water flow over time. Constructed from a blend of petroleum based waxes, microcrystalline waxes, and sometimes reinforced with fiber mesh, the wax portion of the ring provides the malleability needed to conform to irregular surfaces. The wax is formulated to remain flexible enough to create a tight seal when compressed by the toilet’s weight yet firm enough to maintain its shape under varying temperature and humidity conditions. The horn’s material is chosen for durability and resistance to corrosion, ensuring it remains intact even with prolonged exposure to water and cleaning chemicals. Installation of a wax ring with horn follows a straightforward process but offers added confidence in the seal’s integrity. The ring is centered on the drain flange with the horn pointing upward, and the toilet is carefully lowered onto the ring, allowing the horn to insert into the toilet’s outlet. As the toilet is bolted down, the wax compresses to form a watertight seal around the flange, while the horn creates a secure connection within the pipe. This design is particularly advantageous for DIY installations, as the horn provides a visual guide for proper alignment, reducing the risk of misplacement that could lead to leaks. In commercial settings, where toilets experience heavy usage, wax rings with horns are preferred for their enhanced reliability. They are especially useful in older buildings with worn flanges or slight structural irregularities, as the horn compensates for minor imperfections that might compromise a standard wax ring. Additionally, the horn helps maintain the seal during minor toilet movements caused by frequent use, extending the lifespan of the installation and reducing maintenance needs. Plumbers often recommend wax rings with horns for first time installations and replacements, as they offer an extra layer of protection against common sealing failures. The combination of the conformable wax and rigid horn ensures that both the flange to floor connection and the pipe to pipe junction are properly sealed, providing peace of mind for homeowners and facility managers alike. As a result, wax rings with horns have become a standard choice for professionals seeking to ensure long lasting, leak free toilet installations.